What is an MSHA inspection checklist?

MSHA inspection checklists are documents that safety officers use to monitor mining operations, machinery, and personnel to make sure mine work is being done safely.

Routine mine inspections are key to ensuring safe and successful mining operations. A mine site safety inspection checklist helps inspectors conduct inspections more efficiently, since it ensures they measure specific criteria. MSHA inspection checklists:

- Thoroughly audit jobsite environments, equipment, and vehicles

- Help prepare emergency response plans

- Evaluate mechanics and electrical systems

- Audit on-site offices

- Clarify road & surface requirements

- Ensure that you follow Mine Safety and Health Administration (MSHA) rules and regulations

Using a mine site safety inspection checklist guides professional miners through necessary protective measures which address fire outbreaks, equipment mishaps, respiratory danger, and other relevant hazards.

By modifying mine inspection templates to meet different safety criteria specific to your business, you can take control of workplace safety and ensure mine workers are following defined safety policies.

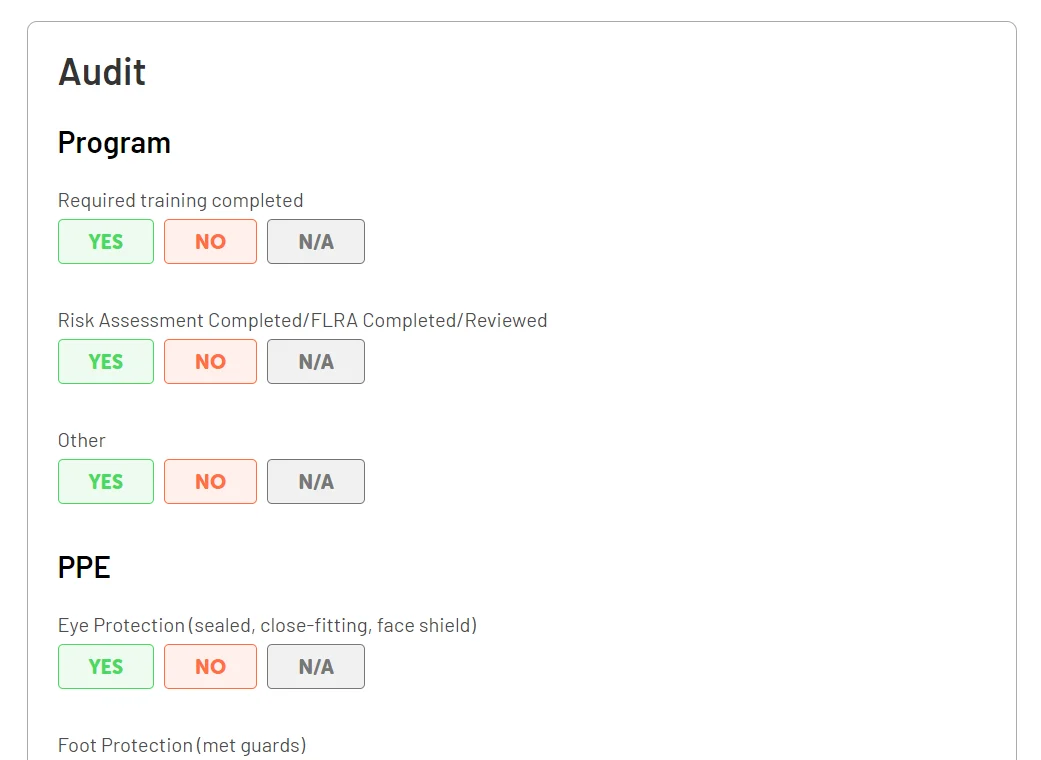

What does an MSHA inspection checklist include?

Mining is one of the riskiest professions, so mine inspections need to be conducted regularly so you can identify workplace hazards. Extreme humidity and temperatures, dust, hazardous gases, and chemicals are just a few examples of potential hazards that exist in mines.

Activities like resource extraction, drilling, blasting, mine development, crushing, and milling use heavy equipment that can easily injure someone. An MSHA inspection checklist checks for any flaws that threaten worker safety, and examines the preventive measures you have in place. Your checklist should address:

Crew and personnel training

Your inspection needs to make sure that mining crews and other employees are qualified to safely perform tasks. One employee’s mistake could lead to delays or injuries onsite. Employees who haven’t been trained and employees who are sick should not be working.

Your workers are required to complete Hazard Communication Program (HazCom) before they can do mine work. HazCom’s main goal is to protect employees at work from accidents and dangerous materials. Inspections need to make sure that mine sites adhere the HazCom hazard prevention procedures, which include properly marking and storing hazardous items.

Equipment condition

Mine equipment and machinery checks are always part of an MSHA inspection checklist. Regularly inspecting your equipment reduces the possibility of work-related accidents. Being proactive about the condition of mining machinery is key to preventing small issues from escalating.

Fire safety measures

Mine workers must be given personal protective equipment and you need to follow fire safety precautions in your workplace. Inspectors need check for fire hazards and maintain safety measures, such as “no smoking” signs. Fire extinguishers, hydrants, and other safety supplies must be easily accessible. It’s easier to resolve issues if you MSHA inspection checklist includes a mine safety plan.

Roads and surfaces

Inspect the entirety of your site premises for irregularities. Any roads leading to the mining site need to be in good, working condition before being used to haul mining materials. Site surfaces need to be firm and sturdy so they do not collapse.

Common mining safety measures

Different MSHA inspection checklists are used to inspect separate areas of mines. Wherever your employees are working, there are a host of general safety measures you should implement:

-

- Train your workers to observe preventive hazard procedures at work

-

- Make sure miners understand and can follow your emergency safety plan

-

- Train miner to safely use, maintain, and dispose of their PPE

-

- Organize lifting training, since heavy lifting can be dangerous when done improperly

-

- Ensure the worksite is well-lit so that workers can see and navigate safely. Underground pathways should also be lit up to enhance visibility.

-

- Make sure your workers wear necessary personal protective equipment like goggles and masks

-

- Be mindful of the extreme temperatures in mines, and don’t require extra-long hours

-

- Prioritize communication between you and your crew regarding the progress of mining activities

-

- Set up rock bust safety measures to prevent falling rock pieces from injuring anyone, by using blast mats, fastening anchors, and other protective equipment

-

- Ensure that noise levels are kept at an acceptable frequency and vibrations are controlled

-

- Keep your surroundings, offices, and toilets neat and hygienic.

-

- Inspect all heavy vehicles used for hauling and address and faults before use

-

- All equipment should be kept clean and regularly maintained to avoid equipment mishaps

Streamline your MSHA inspection checklists with workflow automation software

Because mining is such a high-risk occupation, it’s vital that your safety inspections cover everything. When you rely on paper checklists, it’s easy to miss a step or for different inspectors to do things differently. That’s where Lumiform’s workflow automation platform comes in, ensuring that you perform consistent, thorough inspections.

The mobile app and desktop software make it easy to create MSHA inspection checklists in minutes, and complete them no matter where you are. Monitor the progress of inspections in real-time and receive alerts whenever one of your workers finds an issue. You and your team will be able to:

-

- Conduct inspections from your smartphone or tablet with the mobile app

-

- Conduct more comprehensive inspections by including photos and videos of various issues as points of reference

-

- Resolve issues faster thanks to automatic alerts when something goes wrong or a hazard is found

-

- Use Lumiform’s EHS software to find problems and take corrective actions 4x faster

-

- Automatically generate reports, data, and analysis, so you can learn from the results of inspections and improve worksite safety